What is a Countersink Bit?

What is a Countersink Bit?

A

countersink bit is a type of drill bit that allows you to widen the

entrance to a pilot hole so that the screw head is flush with the

surrounding metal rather than sticking out on top of it.

The countersink cannot be used to drill holes; instead, its unique shape is

designed to create shallow, wide holes in which the head of a screw fits

perfectly.

Making a countersink hole in metal is a process that requires high precision as it involves part aesthetics. While it is relatively straightforward, it requires a level of technicality so as to avoid damaging metal parts during the process.

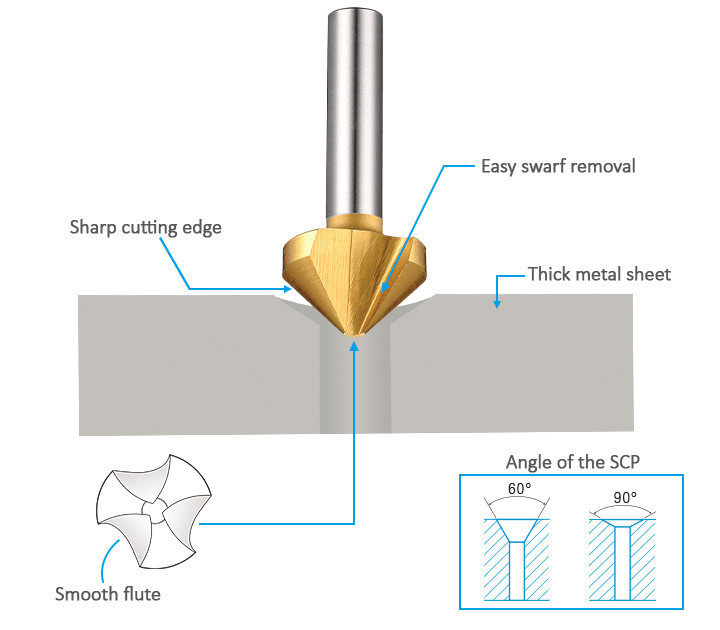

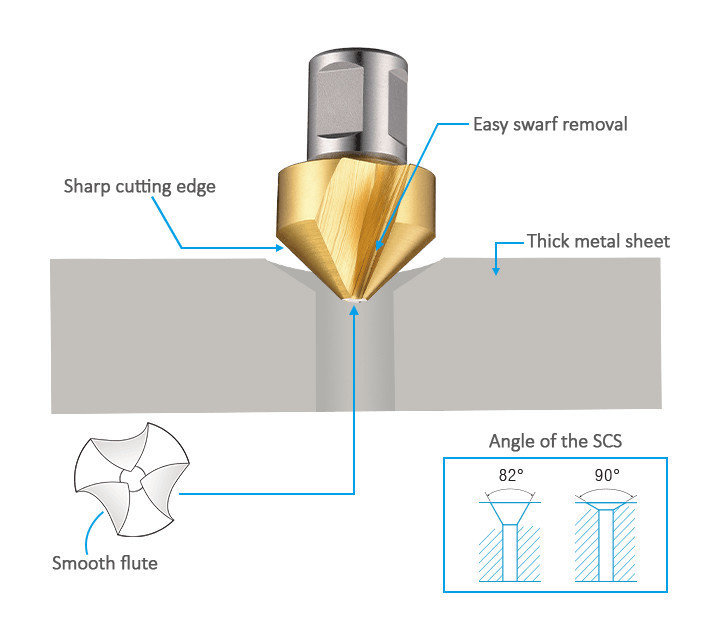

Countersink Features?

For Portable or Pillar Drilling Machine

For Magnetic Drilling Machine

Countersink Angle

60° (Deburring)

The primary purpose of this countersink angle is to remove burrs or sharp edges from the screw area of a metal part. After deburring, the metal has smoother edges.

82° and 90° (Countersank Screw)

There are two angles for countersunk screws. However, the exact angle chosen is a function of the industry countersink screw standard. For instance, the US standardis 800 while other countries use 900 countersunk screws and same angles.

When to use a Countersink Drill Bit?

A countersink can be used for a variety of reasons. A tapered countersink bit is a versatile drill bit that can be used to countersink screws beneath the surface or completely hide screws, deburr material, prevent tearing, or eliminate hazards.

Hide Fasteners

By drilling a countersink slightly deeper than the fastener head, you can completely conceal the fastener. To fill the hole, cover the fastener head with woodfiller, and give the appearance of smooth, undisturbed wood, wood plugs.

Deburr Material

Burrs can form when drilling a hole through metal or plastic. A burr is an unwanted projection of material produced by machining. By removing the deburred portion, a countersink can be used to deburr the sides of the hole.

Prevent Tear-Out

A screw's threaded body cuts through wood as it advances. The threads on the fastener heads have been removed. Instead of cutting the wood, it grabs and pulls the fibers, resulting in a tearing out mess.

Tearing out is especially common when inserting fasteners into hardwoods. For the best results, the countersunk pilot hole should be the same size as the tip of the screw or fastener you’re installing.

Eliminate Hazards

A protruding screw or other fastener on a smooth surface can cause problems. When this occurs on a floor they can pose a tripping hazard. furthermore, protruding screw heads can cause scratches and deep cuts on the hands or you can get stuck on them with your clothes. These risks are eliminated by galvanizing your fasteners.

How to use Countersink Bit?

To make a pilot hole, choose a drill bit that matches the size of the screw.

Step 3. Drill the countersunk hole

Choose a countersink that matches the angle of the screw head. Insert the bit into the drill.

Then drill the hole deep enough to make the screw head flush with the surface of the wood. Or drill the hole deep enough to hide the screw head with a filler.

Step 4. Install the screw

Use a screwdriver or drill to drive the screw into the countersunk hole. Make sure the head of the drill fits snugly with the countersink and does not protrude above the surface of the wood. If this is the case, you can remove the screw again and perform all the steps again.

Support

Countersink are one of the popular products of 3keego, with a wide range of drilling machines to choose from depending on what type of working conditions. From smallest holes to narrow and large working space, 3keego got it for you.

If you have any further questions, please do not hesitate to CONTACT US .