How to drill Thick and Large Diameter Holes?

Drilling through metal can be challenging at the best of times, but trying to create a large diameter hole can present even more of a dilemma, especially in a substantial steel beam or plate.

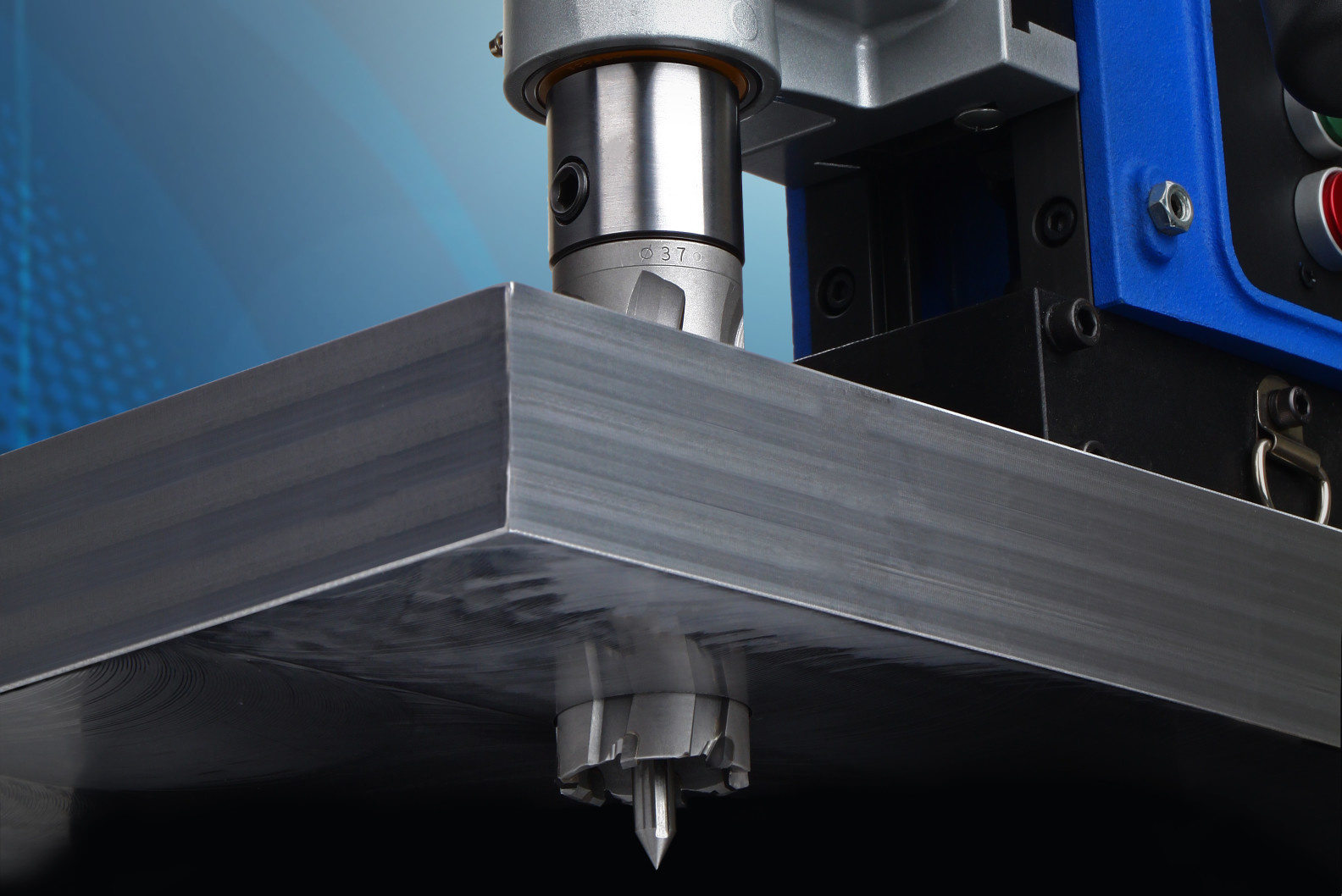

HCLF Annular Cutter with a drill depth of 10" (250 mm) are equipped with a spiral flute which creates optimum chip removal and makes seizure next to impossible. These carbide cutting tools are used to drill in hardened materials such as thick metal sheet.

HCLF Annular Cutter 250 mm cutting depth are less susceptible to

breakage than High Speed Steel Cutters, especially in larger

diameters and lengths.

Menu

Highlights and Features of the HCLF Annular Cutter

Clean Drilled Hole

How to drill thick metal sheet

Watch HCLF Video

Support

[ Highlights and Features of the HCLF Annular Cutter ]

Drilling holes on thick and large diameter holes is a specialist task and requires the right equipment and setup.

The correct cutting tools are also required, and 3Keego have developed a generation of cutting tools for exactly this purpose.

They are also tipped with individually brazed cutting teeth of the highest quality carbide and have been designed with an elaborate cutting geometry which results in faster, quieter, easier drilling and chatter free performance.

This quality product is suitable for all metals, such as thick steel and cast iron, but was specially developed for harder materials with thick and large diameter holes.

Perfect for fabrication, steelworks and metal modification industries, or any job that requires a fast and reliable tool that cuts through the harshest of metals.

The fluted shape, for chip collection and faster removal, can avoid overheating to extend the service life of HCLF Annular Cutter.

Besides, if the chips can be removed over the flute quickly, the drilling process will also become faster.

Clean Drilled Hole?

[ Application of HCLF Annular Cutter ]

For Thick metal sheets

Metal sheet up to 250mm depth, and up 150mm diameter hole.

[Advantages of HCLF Annular Cutter]

[How to drill thick metal sheet?]

Summing up the topic, the right method can make a real difference in

how smoothly the operation goes. To systematize knowledge before

drilling thick metal sheet it's worth remembering three important

tips:

1. Proper annular cutter like HCLF for thick metal plate

The annular cutter to drill thick metal plate is Tungsten Carbide

Tipped annular cutter. Thanks to their properties they can easily cut

through without damaging the surface. Sintered and finished carbide has

a combination of compressive strength, extreme hot hardness at high

temperatures, and resistance to abrasion, corrosion, and thermal shock.

These are important factors in drilling hard and thick materials because

the friction of metal against metal can produce high temperatures. That

damage the material or the drill bit.

2. Set the right rpm and keep an eye on the chips

The set the rpm’s for metal sheet is usually about 50% less than mild

steel. The trick is to use slow rpm and more feed pressure than is used

with steel. An annoying, high squealing sound means that the rpm is too

fast. Keep an eye on chips. When they are gold or blue, the drilling

machine is running too fast. Drill swarf should come off in long

spirals, not small chips.

3. Remember about coolant

Coolant is used to keep the cutter cool. During drilling through metal

sheet heat is absorbed into hole cutters. Due to generated extreme heat,

cutters quickly become dull or softened. It's recommended to place a few

drops of cutting oil on the surface of the stainless steel before

beginning to drill. Periodically add more oil drops, until you have

drilled completely through the stainless steel.