What is a step drill/ step bit/ step drill bit?

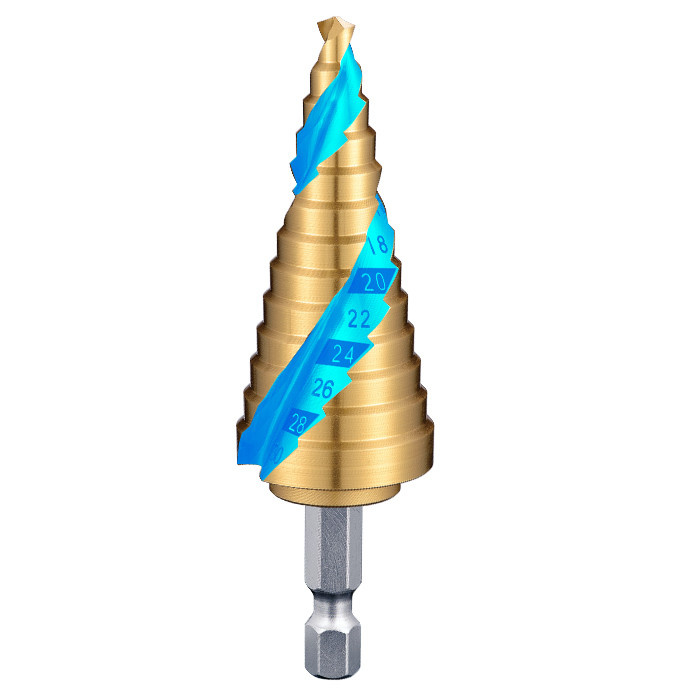

A step drill , also known as stepped drill bit, step drill bit or step bit, is a conical drill bit with increasing diameters step by step. A step bit can be made of steel, high speed steel and cobalt or carbide tipped for drilling holes through soft materials like aluminum, plastics and wood,and hard materials such as bronze, cast iron and steel.

Sometimes, step drills will be coated by TiN (titanium-nitride) and TiAlN (titanium-aluminum-nitride) which makes it harder and more durable to offer a longer service life.

Menu

Highlights and Features of the Step Drill

What is a Step Drill Used For?

Application of Step Drill

Advantages of Step Drill

Watch Step Drill Video

Support

[ Highlights and Features of the Step Drill ]

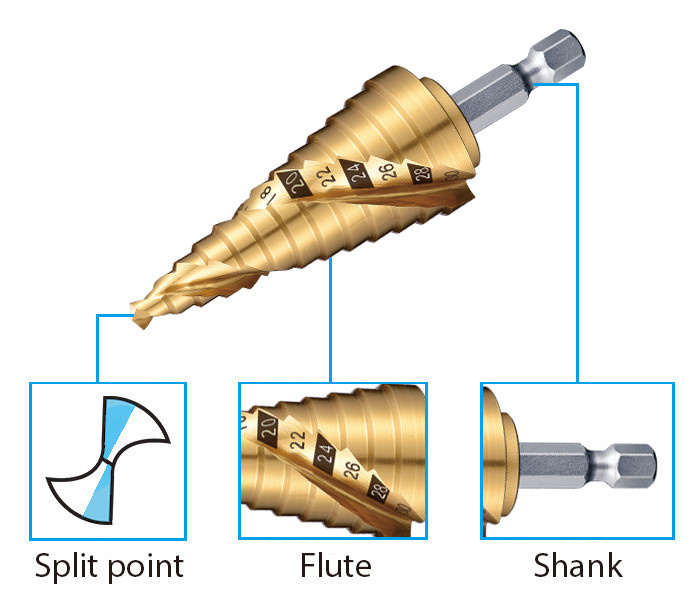

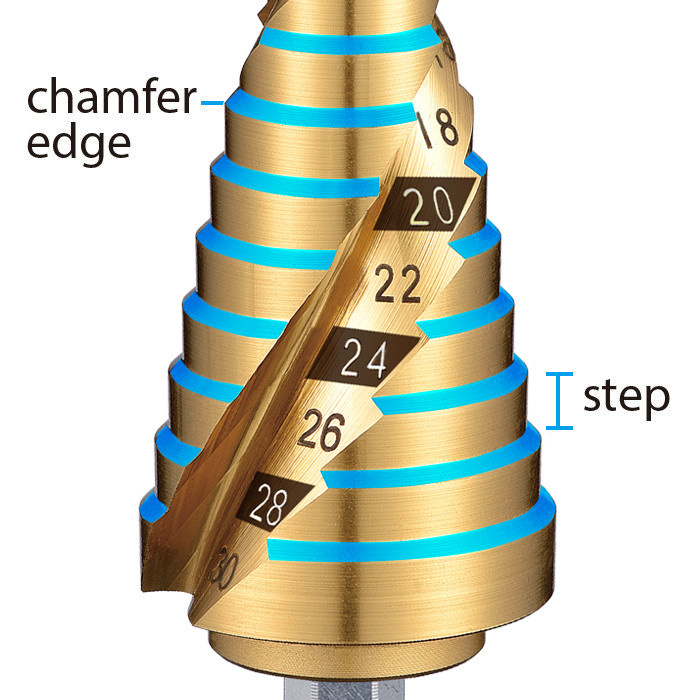

The design of split point tip,

which has a thinner cutting point,

can help the step drill catch the

workpiece to ensure the step drill

will not drift by added pressure

when starting drilling.

As a result, no need for center punching when drilling holes with a step drill.

The fluted shape, for chip collection and faster removal, can avoid overheating to extend the service life of the step drill.

Besides, if the chips can be removed over the flute quickly, the drilling process will also become faster. A spiral fluted step drill can remove chips better than a straight fluted one.

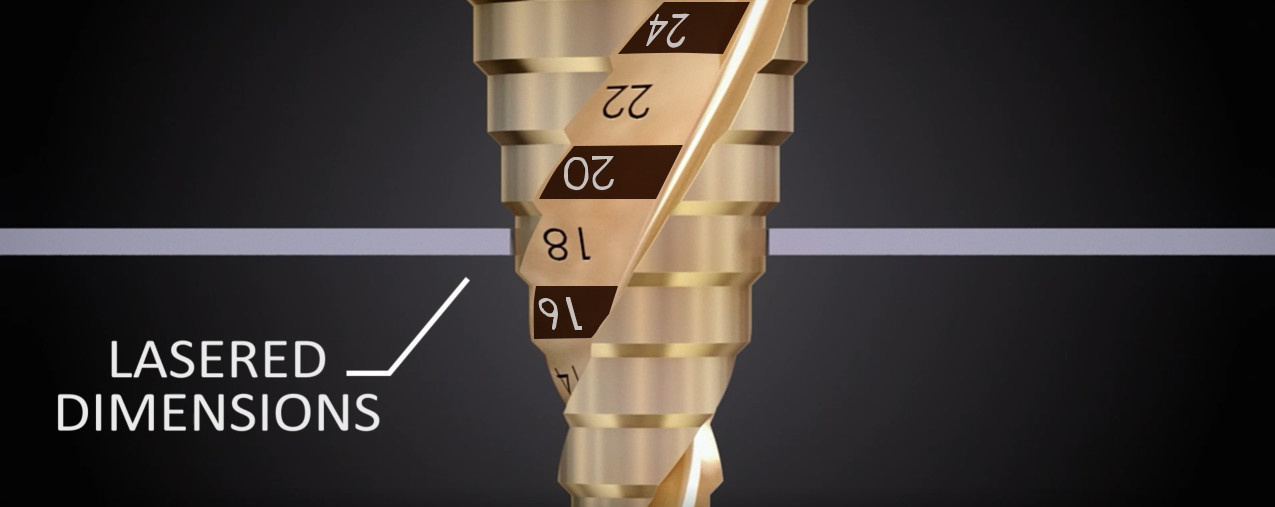

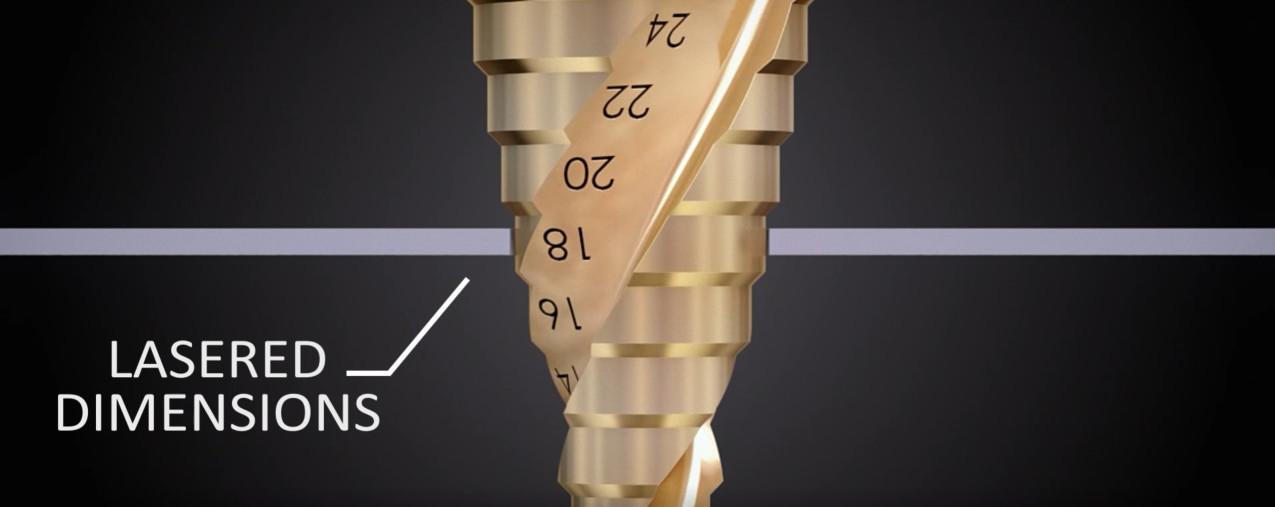

Lasered dimension for easy visual.

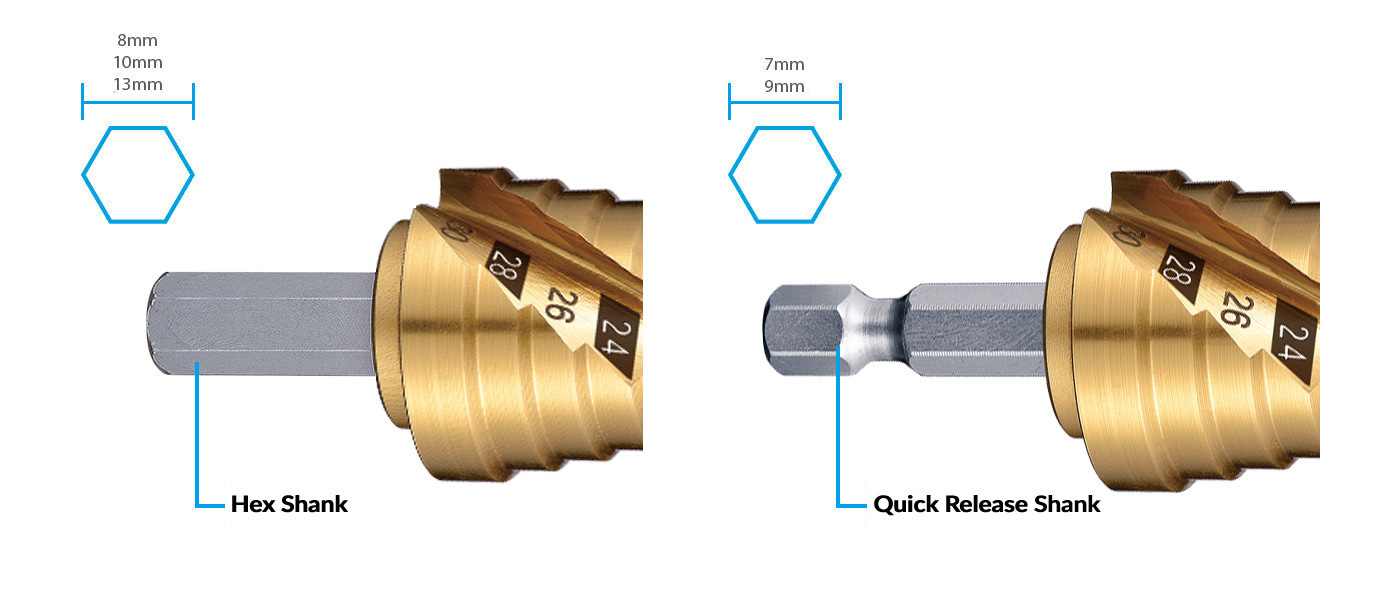

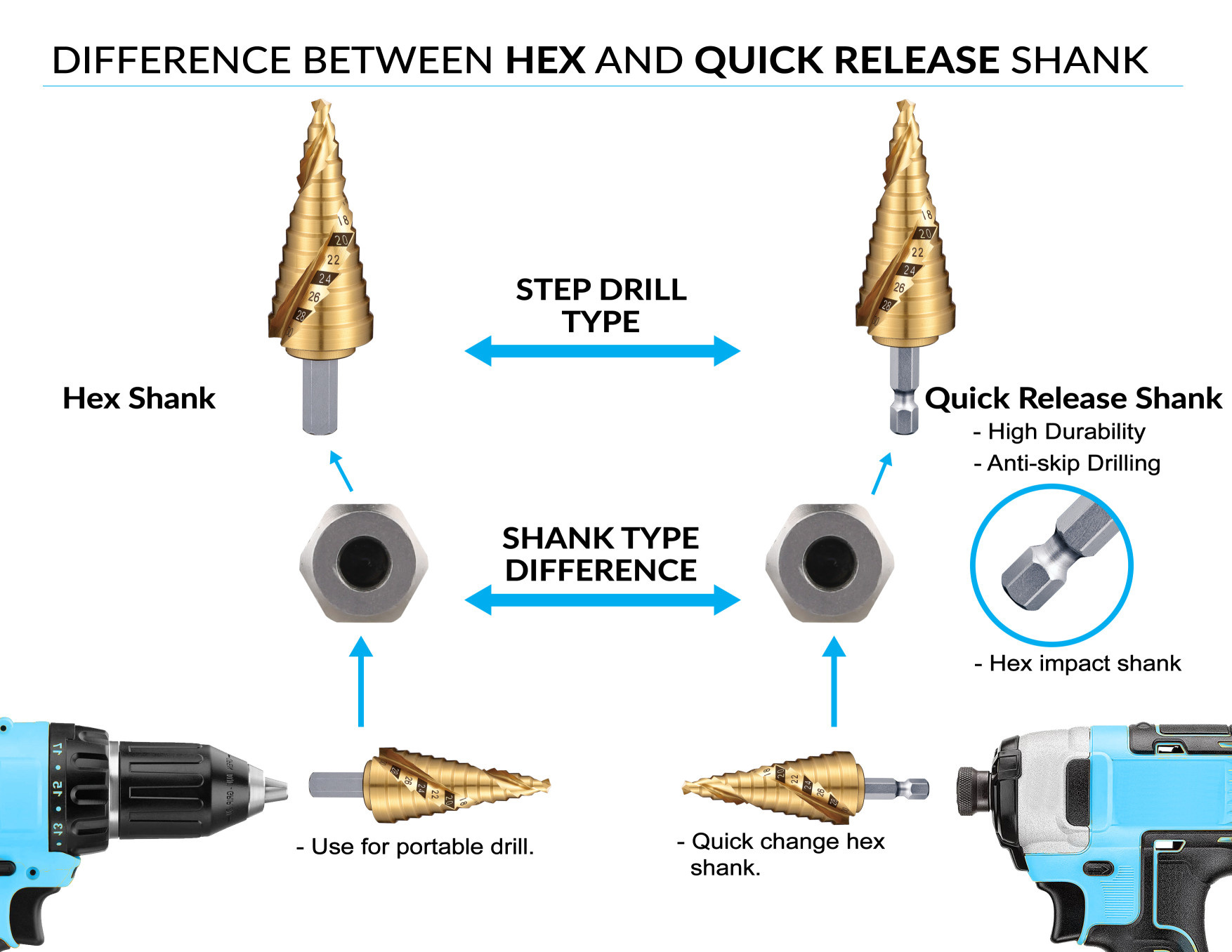

Difference Hex Shank and Quick Shank ?

What is a Step Drill used for ?

[ Application of Step Drill ]

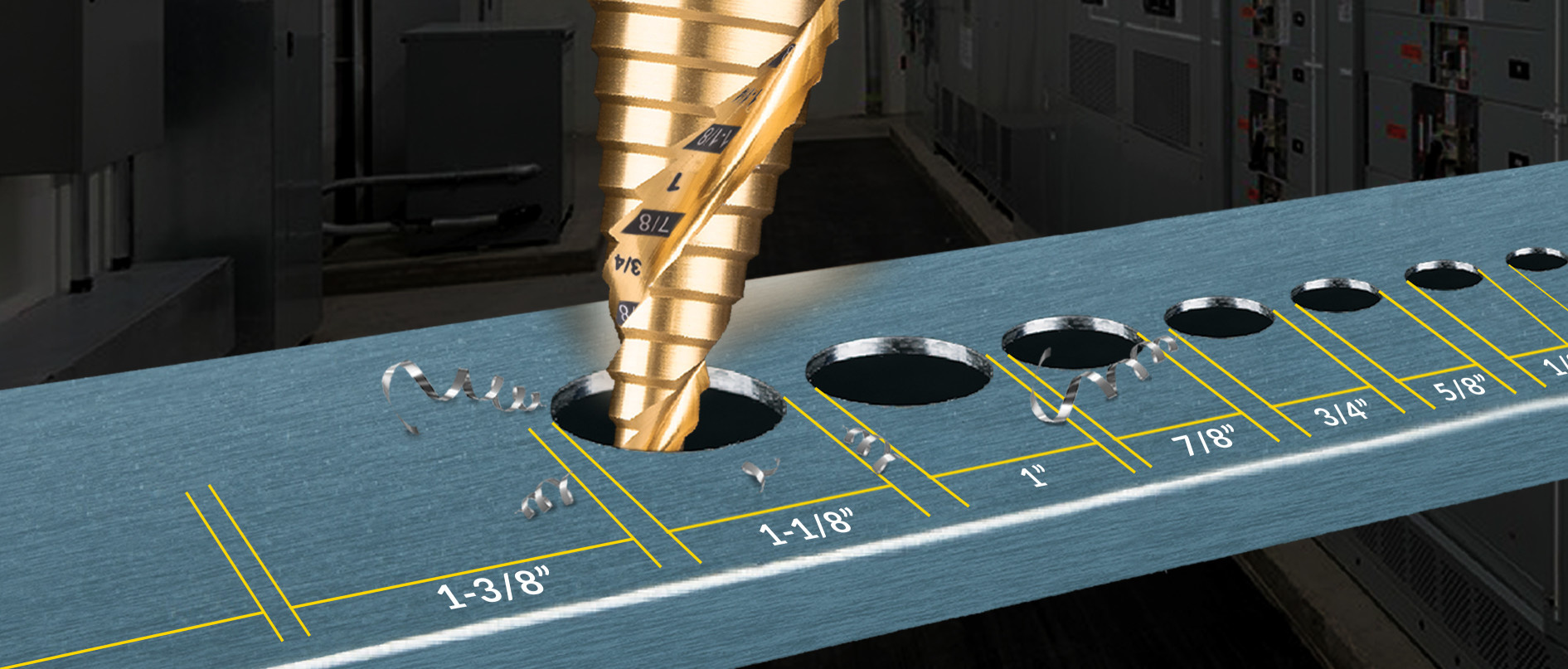

For Thin Materials (up to 4 mm)

Metal, Stainless steel, Cast iron, Aluminum, Copper, Bronze, Fiber glass, Plastic, Acrylic, Wood.

Industry and Career

General construction

Mechanical engineering- panels and covers, switching systems

Automotive industry - chassis

Aviation industry

HVAC (heating, ventilation and air conditioning) system

Sanitary engineering

Electrician - electrical boxes, project enclosures

Glaziers -fiber glass

Carpenters -wood, plywood, particle board

Housings