Why Drill Metal with Annular Cutter (Mag Drill Bits) in Magnetic Drill?

Menu

What is an Annular Cutter (Mag Drill Bits)?

Features of Annular Cutter

Why Drill with Annular Cutter (Mag Drill Bits)?

What are Annular Cutter (Mag Drill Bits) Used For?

How to Choose an Annular Cutter (Mag Drill Bits)?

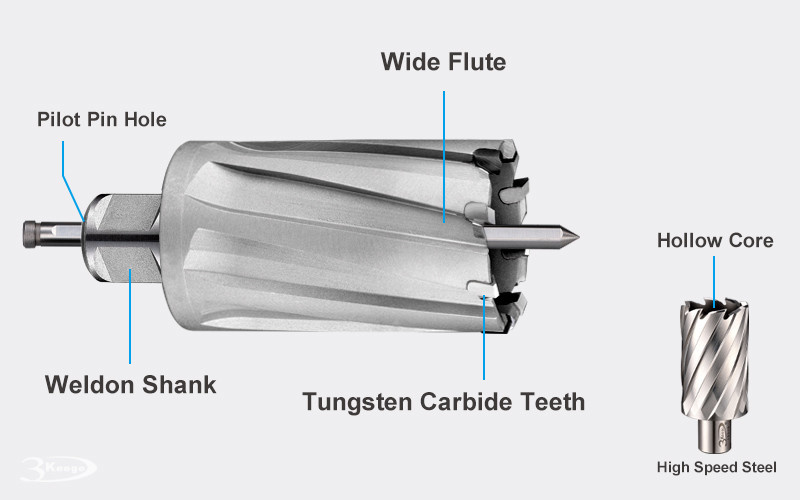

What is an Annular Cutter ( Mag Drill Bits ) ?

An

Annular Cutter, with a center free annulus bell shape, is used to make holes in

metal. It is also known as mag drill bits which is named after the use

in

magnetic drilling machine. Usually, annular cutters are available in

Tungsten Carbide Tipped (TCT)

and

High Speed Steel (HSS).

Features of Annular Cutter

Tungsten Carbide Tipped (TCT) Annular Cutter

Tungsten carbide (WC) is sharper than most materials and about 2 times

harder than steel. It also has hot hardness at high temperatures

allowing faster drilling speed. Besides, tungsten carbide has a very

high wear resistance and its thermal expansion is less than steel. Due

to the TCT cutting edge, the annular cutter can drill hard materials

with a high quality performance.

High Speed Steel (HSS) Annular Cutter

HSS can withstand higher temperatures and keep its hardness to drill

faster than carbon steel, like the name of high speed steel. Mostly, the

HSS annular cutter is made from

M2

steel. In order to drill harder materials, cobalt will be added to steel

to make

M42

type HSS annular cutters. If the cutter becomes blunt, it can be

re-sharpened to use again.

Hollow Core Design

The hollow core design provides the annular cutter an efficient and

quick way to make holes in metal. Compared with conventional drill bits,

annular cutters only contact with the metal by the outer perimeter to

cut the periphery of the hole, instead of removing the whole area of the

hole, and leave a solid slug with less chips.

Multiple Cutting Teeth (for TCT)

The multiple cutting teeth geometry has a faster start drill because it

distributes the cutting surface evenly to lower the friction when

drilling the material.

Flute

During the cutting process, the heat from drilling will transfer to

chips and cause chips to expand which may result in a stuck annular

cutter in the hole. The design of flute can lead the chips out of the

hole smoothly to avoid overheating and jammed.

Weldon Shank

Weldon shank is widely used with magnetic drilling machines. The 2 flat

system will be securely held to prevent from rotating and moving when

start drilling. This provides the annular cutter a longer tool life as

well as an accurate and burr-free hole. Also, you can use an adapter

(from Weldon to your shank type) for the annular cutter to fit different

magnetic drilling machines.

Hole for Pilot Pin

There is a hole in the center of the shank for pilot pin to go through.

A pilot pin plays a very important role in annular cutters. Here are

three functions it provides:

- A pilot pin helps the annular cutter align the center point of the hole.

- The pilot pin will retract into the magnetic drill while starting drilling. This allows the internal coolant to flow down to the cutting teeth of the annular cutter.

- When finishing drilling, the retracted pilot pin will eject the slug.

Titanium Nitride (TiN) Coated and Titanium Aluminum Nitride (TiAlN) Coated

Coated annular cutter is stronger and more durable than standard type.

Coating can prevent the cutter from rust to prolong the tool life. This

coating process allows annular cutters to increase the cutting speed and

drill hard materials.

CBN (Cubic Boron Nitride)-Ground

Cubic Boron Nitride (in a cubic crystal structure) is a super hard

material after diamond. With properties of superior thermal stability

and chemical inertness, CBN is widely used for grinding cutting tools

while diamond will deteriorates when contacting with steel. CBN

processed annular cutter has a better cutting performance by sharp

flutes and cutting edges.

Why Drill with Annular Cutter ( Mag Drill Bits ) ?

Benefits and Advantages of Annular Cutter

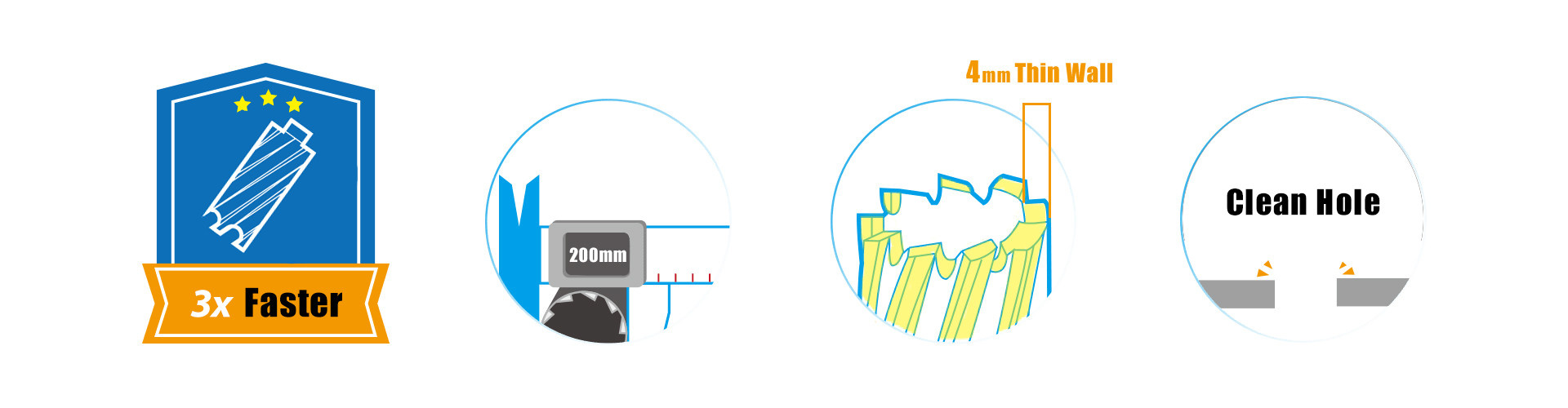

- Fast (Time Saving)

Since an annular cutter removes only the material at the periphery of

the hole, it is 3 to 4 times faster than twist drill bit.

Besides, an annular cutter with pilot pin can finish a hole by one

operation without pre-drilling for a pilot hole.

- Efficient (Energy Saving)

Due to the annulus shape and thin wall design (4mm for each diameter),

the annular cutter does not have to drill the complete material of the

hole which lowers the energy, effort and thrust compared to conventional

drill bits.

- Less wear (Longer life)

While the cutting surface is distributed to multiple cutting edges, the

contact between annular cutter and the material becomes much less.

Also, no matter how big the hole you are going to drill, the thin wall

(4mm) of the annular cutter will cut only at the periphery of the hole.

Therefore, an annular cutter with a good design has a longer service

life with best performance.

- Clean Hole (Burr-free)

With specially designed cutting teeth geometry compared to conventional

drill bits, an annular cutter can create a burr-free hole in metal.

Besides, since there is only a few chips made, the cleaning work after

drilling is very easy and fast.

What are Annular Cutter (Mag Drill Bits) Used For?

Material

Cast Iron

Carbon Steel

Hardox

Heat Treated Steel

High Tensile Steel

Metal Sheets

Structural Steel

Stainless Steel

Stacked Steel

Thick Plate Steel

How to Choose an Annular Cutter (Mag Drill Bits)?

Depth:

One of the cutter size determination. The depth will be longer than the

thickness of the material you are going to drill.

Diameter: Outer diameter of the cutter. For small diameter holes, you can choose

a HSS annular cutter. If you need a bigger hole, TCT annular cutters are recommended.

Type of the Material: If you need to drill harder material, TCT or Tin/Tia coated annular

cutter is a better choice.

Shank:

Annular cutters with Weldon shank can be used with most magnetic drills.

If the mag drill you have cannot fit Weldon shank, you can use an adapter.

Support

As we are specialized in Cutting Tools, custom sizes of annular cutters for up to 200 mm in diameter and

250 mm in cutting length are available. We have helped customers solve their problems of cutting holes. You

can search more information on our product category page of

Annular Cutter.

If you have any further questions, please do not hesitate to

CONTACT US.

Related Articles