What is Magnetic Drilling Machine?

What is Magnetic Drilling Machine?

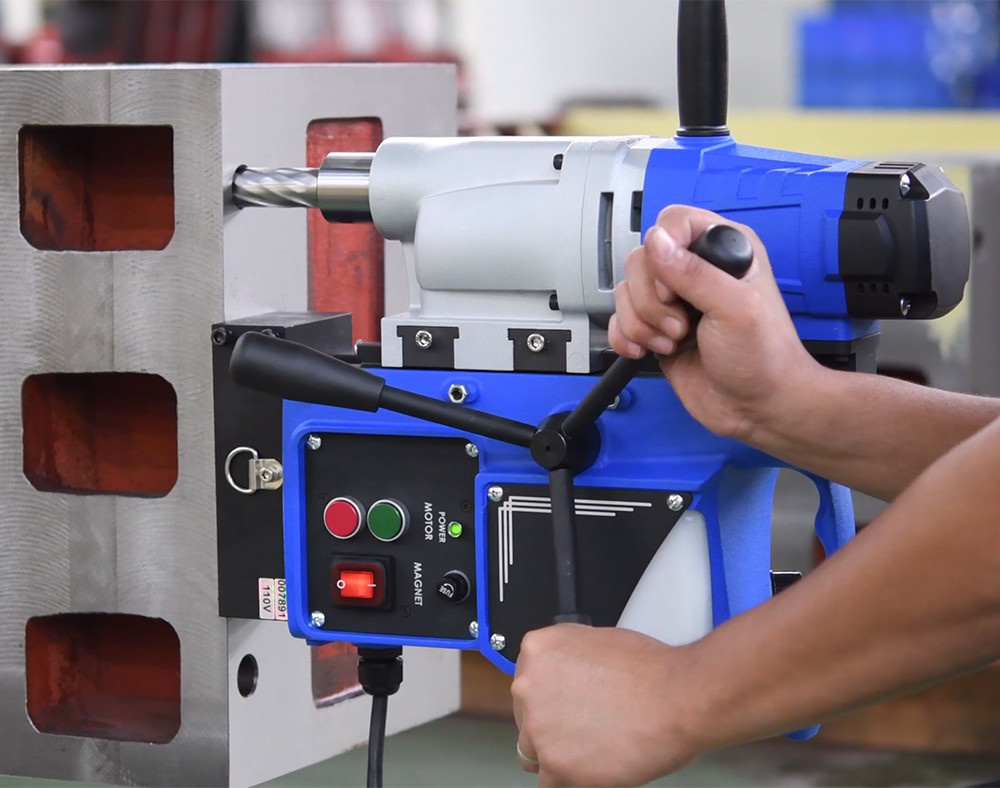

A magnetic drilling machine is used for cutting holes in metals on the worksite. It is a portable machine with a magnetic base (electronic or permanent magnet base) and cutting tool attachment.

Equipped with a strong magnetic base, the portable magnetic drilling machine is able to adhere to steel or other magnetic materials (ferrous metal) surface horizontally, vertically, or upside down. When with suitable cutting tools, such as annular cutters, core drills, twist drills, countersinks and other rotary cutters, a magnetic drilling machine can drill, tap threads, countersink and ream. A magnetic drilling machine is also known as portable magnetic drill, magnetic drill press, magnetic core-drilling machine, mag base drill or mag drill .

A magnetic drilling machine is also known as portable magnetic drill, magnetic drill press, magnetic core-drilling machine, mag base drill or mag drill.

Compose of Magnetic Drilling Machine?

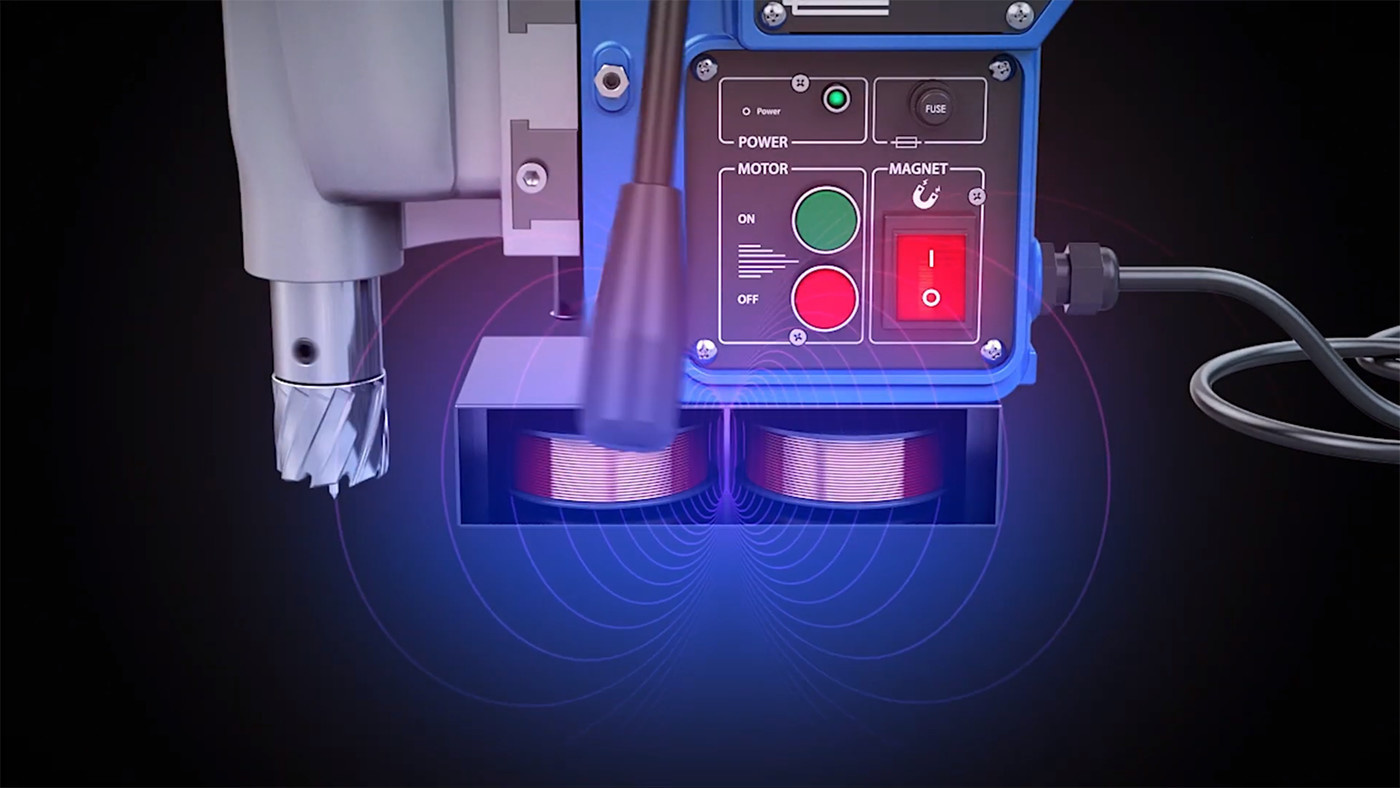

Magnetic Base

The magnet helps the magnetic drilling machine adhere on the metallic material surface steadily. When open the switch, separating from drilling switch, an electric current goes through the coil of wire to produce the magnetic field.

It is noticeable that the thickness of the metal work piece will affect the strength of the magnet base. If the material is not thick enough, the magnetic force will be too weak to hold the mag drill well.

Later, this article will show you Where to use the magnetic drilling machine?

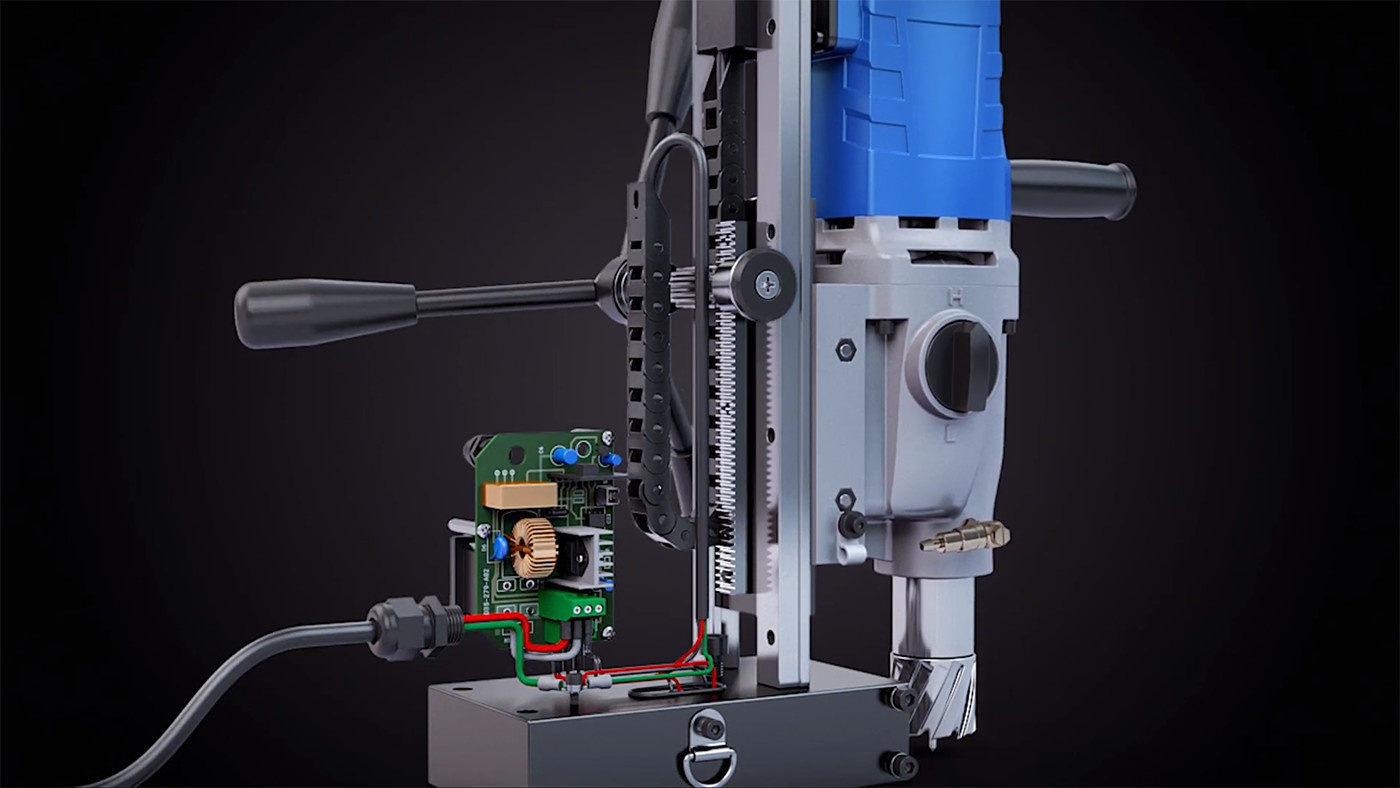

Machine Body

The magnet base, control panel, handle lever, motor and gear box are mounted in the stand part. The slide system of the magnetic drill press helps the motor move upward and downward. It's worth noting that 3keego's SMD35B, SMD50B and SMD75B is designed in novel shape with coolant tank inside. Besides, the structure of magnetic drill is all made of cast aluminum making the machine signicantly stronger and lighter.

The Advantages of Build-in Cooling System

- Smooth coolant flow gets to cutting teeth instead of spinning off during drilling.

- Help the slug eject smoothly when finishing drilling.

- No need to bring a coolant tank and coolant separately.

- Provide good cutting performance.

- Extend cutting tool life.

- No danger caused by long connected coolant tube.

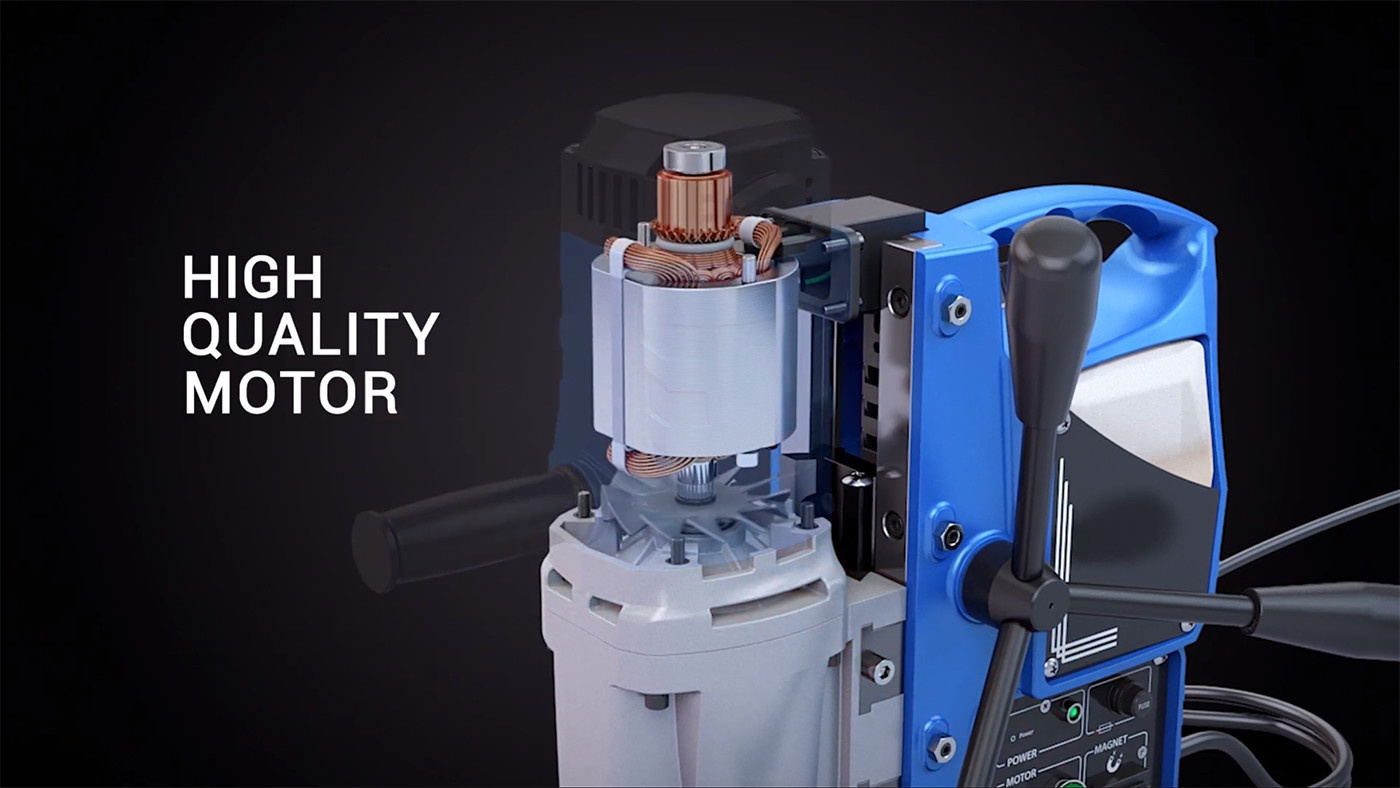

Motor

Choose the motor type depend on the drilling requirement, such as material and thickness of work piece, diameter of hole, drilling speed. Our magnetic drilling machine is equipped with 110V or 220V AC motor. The motor power ranges from 1050 watts to 1600 watts. The larger the diameter hole is the more powerful motor will be needed.

Oil Bathed Gearbox

Unlike grease, an oil bathed gear box is in liquid state at all times. Therefore, the whole gear will be lubricated and protected by oil in cold or hot temperature for a longer service time of the magnetic drilling machine.

Chuck

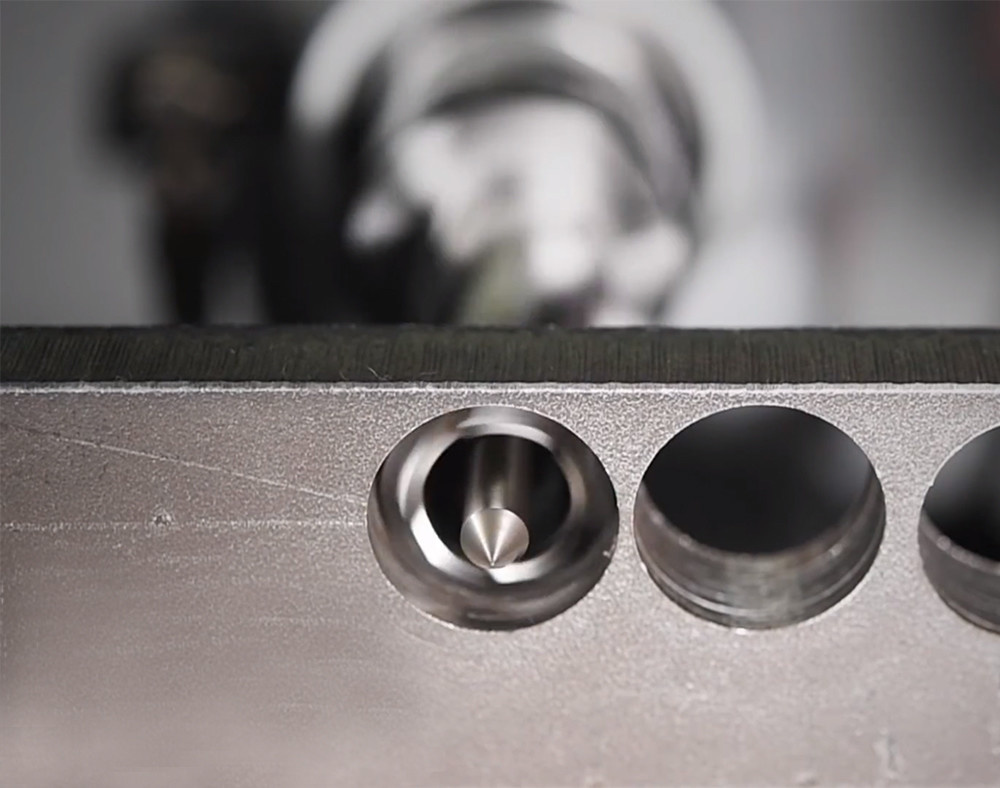

A chuck, also known as arbor or tool holder attached to the motor, is available with M2, M3, M4 Morse taper. When using adapters to fit in it, any type of annular cutters can be used to drilling holes on the work piece.

Where to use the Magnetic Drilling Machine?

A Flat, Solid, Clean and Smooth Ferrous Metal Surface

(a ferrous material includes iron, steel, carbon steel, alloy steel, cast iron, etc.)

No matter which industry field, when using a magnetic drilling machine it should be positioned on a right work piece to prevent shifting and slipping. A clean and smooth metal surface allows the magnet base adhere more strongly and steadily.

Besides, if the material is too thin (thnner than 10mm) or i non-ferrous, it's better and safer than clamlping a steel sheet on top of it for stronger adhesion before drilling holes by the mag drill, especially when drilling holes horizontally or overhead . Most imposrtantly, the magnetic drilling machine should alwasy be fastened with a safety belt (mesh belt) to prevent the mag drill from turning or falling during losing power.

Improper material and operation for magnetic drilling machines

- The thickness of work piece is less than 10mm (3/8") thick.

- The magnet base is not fully positioned on the work piece.

- Put the machine on the steel plate with one or some holes.

- Corrosion, metal chips, debris, dirt, grease, coating and paint on the work piece surface.

- Curved or nonferrous surface without clamp or adapter.

Application of magnetic drlling machine

. Building and construction

. Heavy engineering industry

. Manufacturing industry

. Steel fabrication industry

. Maintenance Facility

. Bridge and Rebuilding

. Ship construction

. Boiler manufacturing

. Pipeline, Offshore and Oil Field

. Railroad Drilling and Railway coach manufacturing

. Automobile, truck, RV and other vehicle industry

. Automobile Repair shop

. Tower and pole construction

. Machinery Rigger

. Wind turbine manufacturing

. Welding industry

Why Use a Magnetic Drilling Machine?

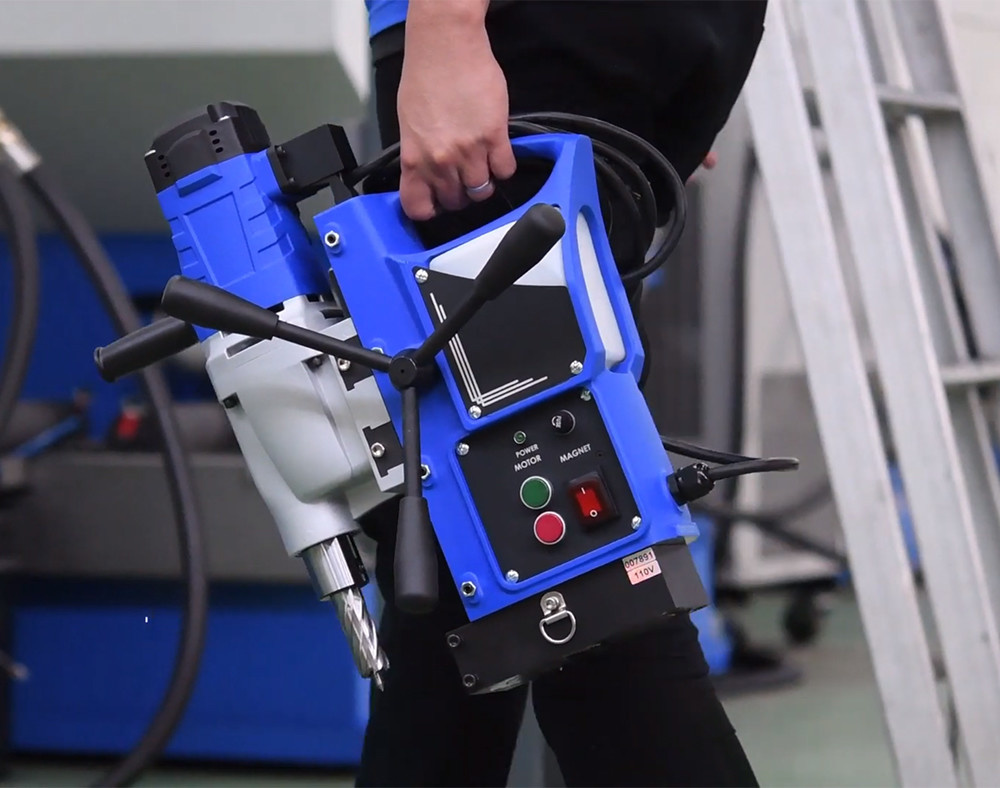

Convenient

Sometimes, the shape or size of the work piece, like ship, bridge or construction, is hard to bring to a work factory and be drilled by standing drill press. For this situation, it is convenient that just take one magnetic drill and cutter to workplace to drill holes on-site.

Flexible

The magnetic drilling machine can adhere to work piece in any position, horizontally, vertically or overhead. Besides, not only annular cutters with a drill chuck, the magnetic drill can drill metal sheet with twist drill, step drill, and countersink.

Fast

Cut large diameter holes only on the periphery by multipoint cutting geometry on annular cutters. Also, not only save drilling time but also save the time of bringing work piece to factory since operators can drill on-site.

Clean and Eco-friendly

When using annular cutter to make a hole, only solid slug and minimal amount of metal chips needed to cleanup. Besides, the solid chunk can be recycled or sell back to the scrap collecting station.

How to Maintain a Magnetic Drilling Machine?

-

Always follow the operating manual.

- A quick examination for anomalies before and after using it.

- Do not over drive or under drive the gear.

- Clean the chips and residual cutting fluid from the machine, slide and links.

- Apply slight grease on the slide system and links of the machine.

- Replace parts that are already worn or damaged.

- Empty the cutting fluid in the container.

- Carry the magnetic drill with packaging box for long distance.

Notice: Unplug the power cable before maintaining the machine.

How to Choose a Magnetic Drilling Machine?

- The maximum diameter of the hole to be drilled.

- The thickness of the material you need to drill.

- The type of material you are going to drill.

- The type of Annular Cutter ( TCT or HSS ).

- The number of holes being drilled.

- Work environment and space limitations.

- Drilling speed requirements (RPM).

- The accessories will be used.

- The industry field you are going to apply.

Why Drill Metal with Annular Cutter in Magnetic Drill?

Support

Magnetic Drilling Machines are one of the popular products of 3keego, with a wide range of drilling machines to choose from depending on what type of working conditions. From smallest holes to narrow and large working space, 3keego got it for you.

If you have any further questions, please do not hesitate to CONTACT US .

Magnetic Drilling Machine Product List