Why Do You Use a Rebar Cutter ? (With Video)

For construction industry or house renovation, Drilling Concrete is UNAVOIDABLE. When drilling a hole into concrete, there is a high chance to encounter the concrete-embedded rebar. The rebar steel can be an obstacle for a standard hammer dill bit to drill through.

Before, people would drill another hole to avoid the rebar when they encountered it. Now, you can use a Rebar Cutter to drill straight through the rebar embedded in concrete without relocating holes.

[ Who Will Use A Rebar Cutter? ]

People who drill holes in reinforced concrete for installing wiring.

Application of Rebar Cutter

Construction Industry

House Renovation

Interior Decoration

Plumbing and Electrical repair

HVAC (heating, ventilation and air conditioning) system

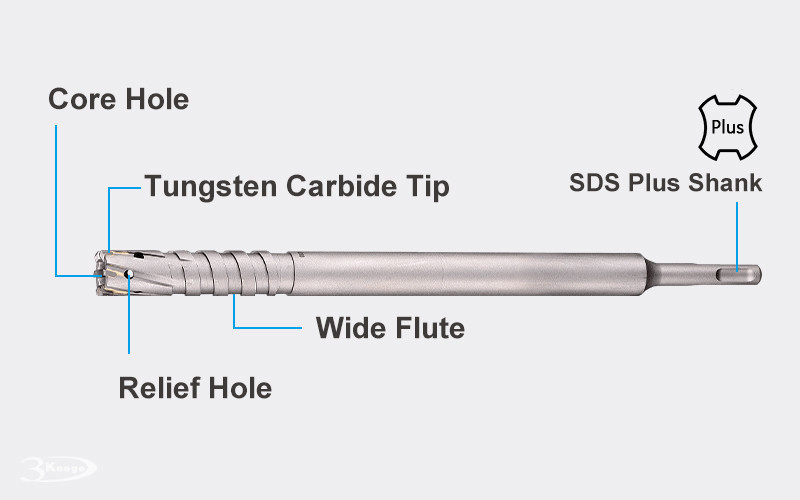

[ Features of Rebar Cutter ]

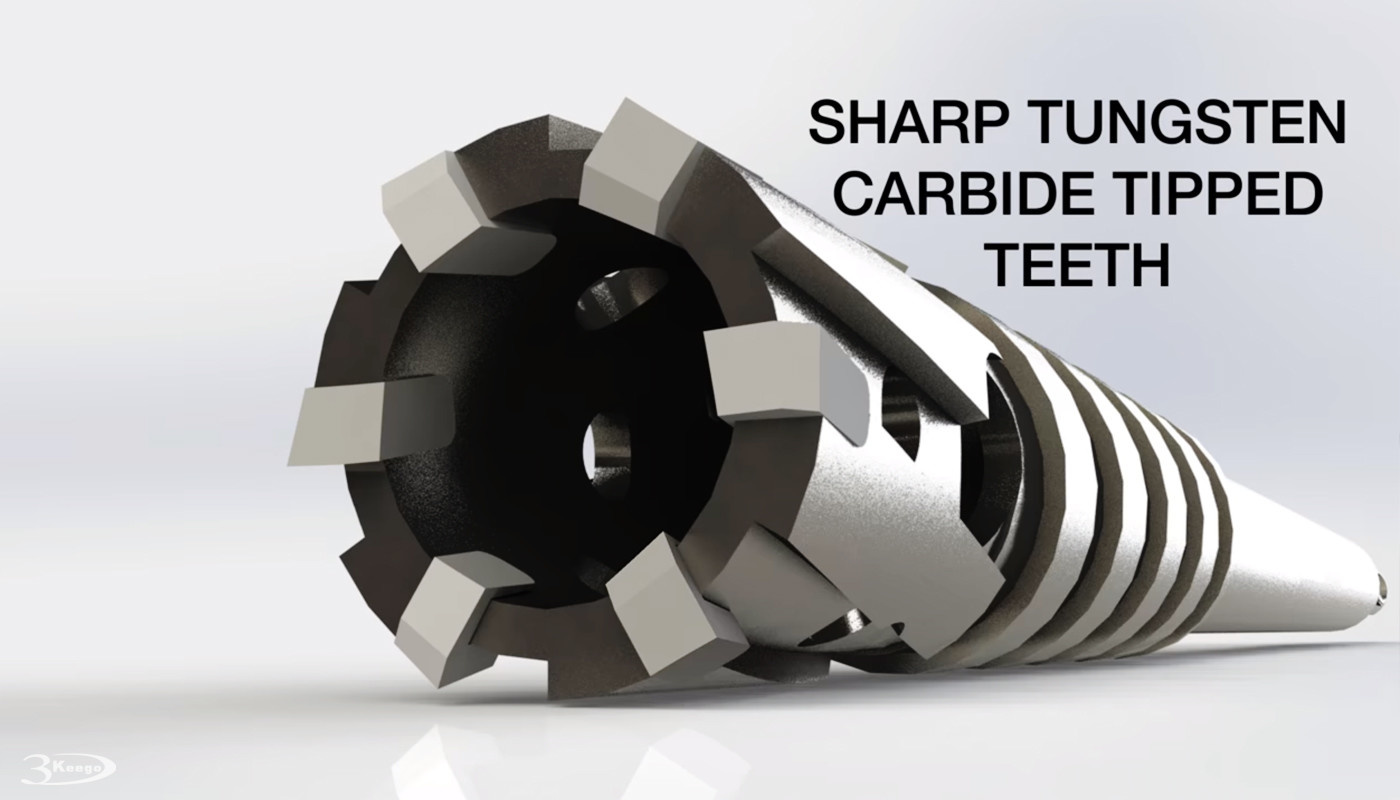

Tungsten Carbide Tipped (TCT) Head

The Tungsten Carbide Tip geometry hardens the head of the rebar cutter to cut through rebar steel fast and easily. The Durable and high-quality tungsten carbide teeth make the rebar cutter more resistant to withstand heat and impact, providing a longer drilling life compared to standard rebar cutters.

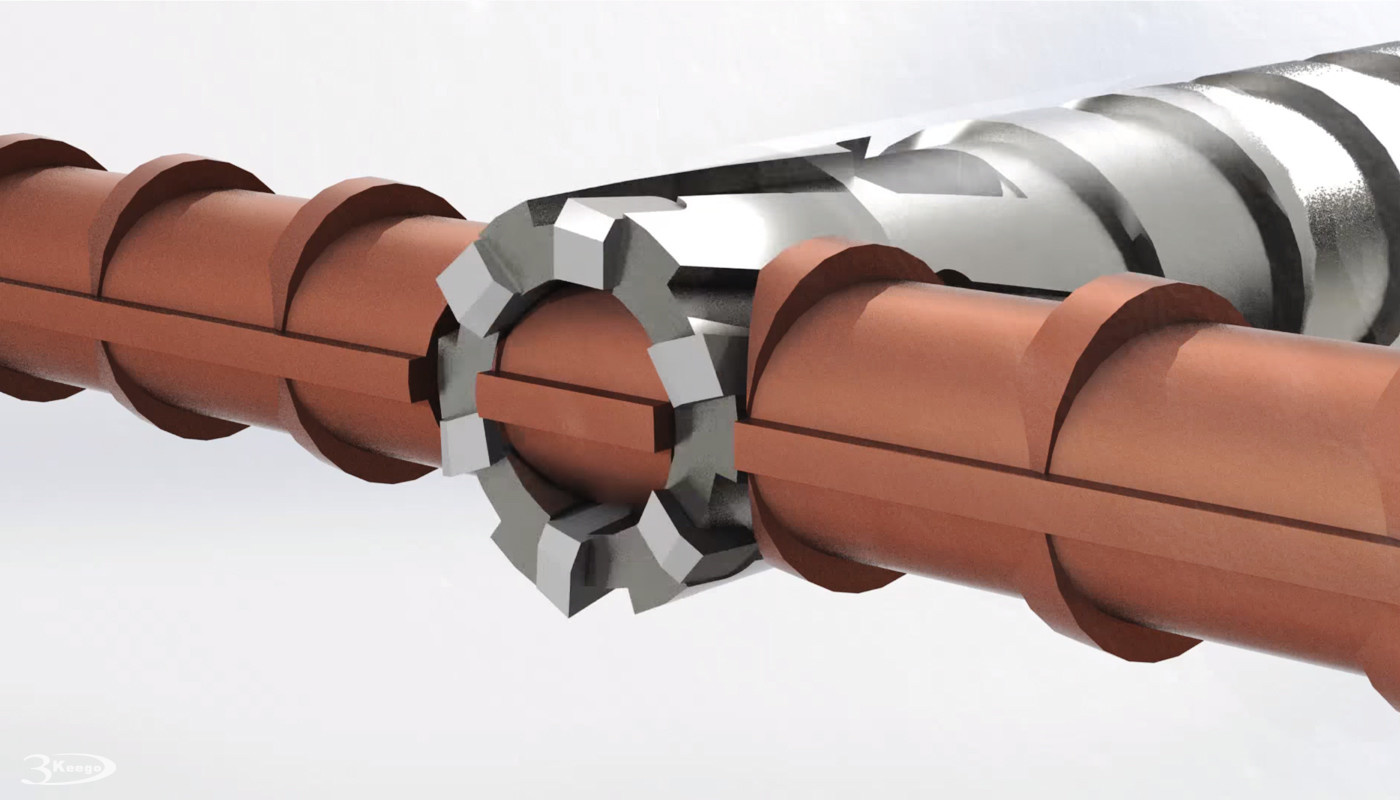

Relief Hole and Core Hole

The annulus shape allows the rebar cutter to cut the rebar steel only on the periphery of the hole and leave a complete slug inside. Therefore, the rebar cutter can drill faster while there is much less steel needed to drill and remove. The less material the rebar cutter drills, the less wear it has. Additionally, the relief hole assists the removal of debris and heat.

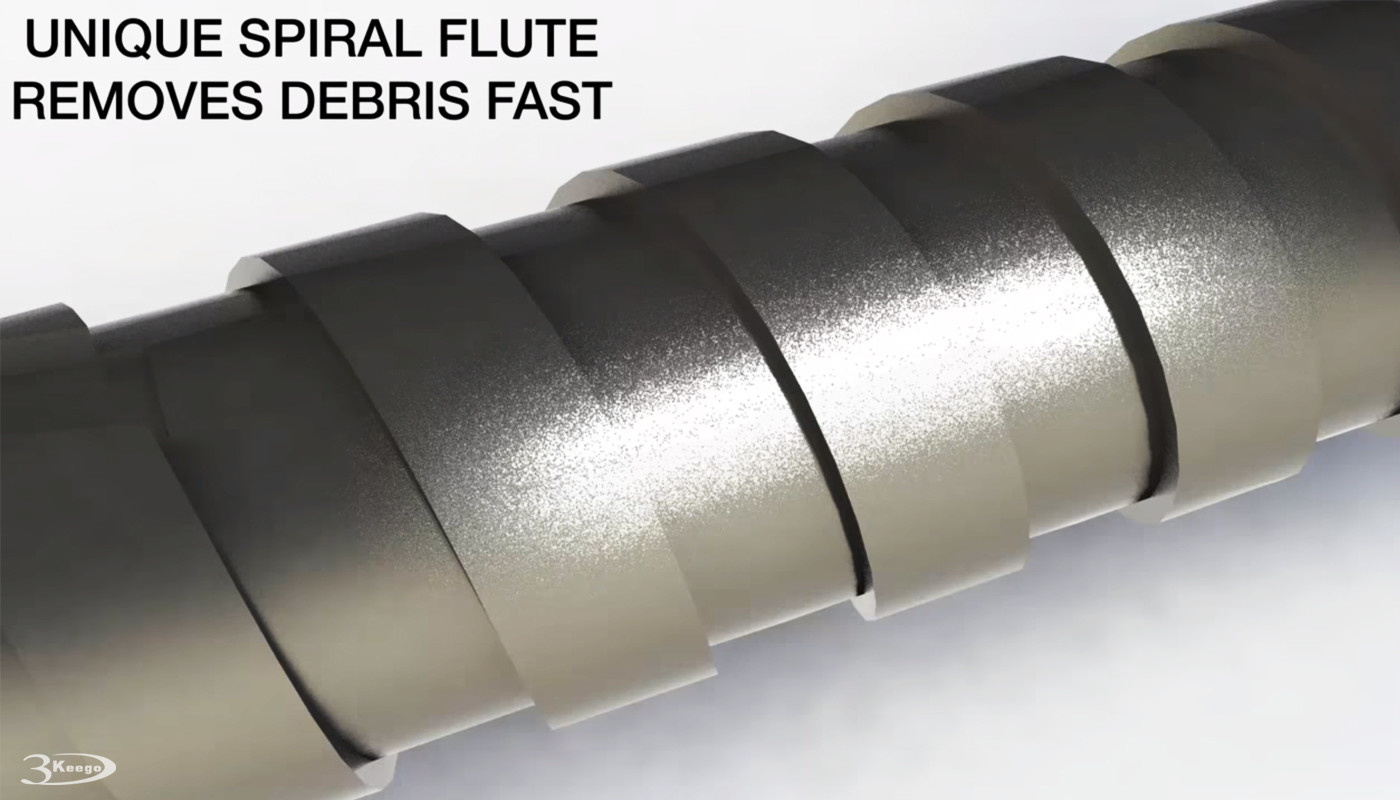

Wide Flute

The flute design of the head part helps the rebar cutter remove chips smoother and faster which prevents the tungsten carbide tips from overheating to extend service life for good performance and durability. Also, there is an optimized spiral flute for the body part of rebar cutter. This flute geometry accelerates the removal of the steel chips and concrete debris.

SDS Plus Shank

The SDS Plus shank, widely used for drilling concrete, is designed for placing into rotary hammer drill which is also the drill for SDS hammer drill bit. This design lets you switch hammer drill bit to rebar cutter easily and quickly. It not only saves time but also saves money as you only need to use one rotary hammer drill.

[Advantages of Rebar Cutter]

Fast (Save Time)

-The unique TCT teeth geometry helps the rebar cutter break the reinforced rebar easily and quickly.

-The material it needs to remove is much less than the standard rebar cutters without the design of core shape.

-No need to pre-drill or step-drilling a pilot hole on the rebar cutter.

Easy (Save Energy)

-Because of the annulus shape, rebar cutter do not have to drill the whole rebar which requires less energy to drill.

-The SDS-plus shank of rebar cutter makes it convenient to fit the same rotary hammer drill also used for SDS hammer drill bit.

-No need to relocate the hole when encountering a rebar. Just drill through rebar together with concrete beside it.

[Notice and Suggestion]

- Make sure the diameter of rebar cutter matches the SDS hammer drill bit.

- Check if the shape of tungsten carbide tip is complete and good before starting drilling.

- Consult with structural engineer or architect before drilling rebar embedded in concrete.

- Turn the hammer drill to rotary mode when using rebar cutter.

While SDS hammer drill bit drills concrete in hammer mode, please do not forget to change the mode to rotary mode if using rebar cutter.

- Do not use rebar cutter to drill concrete during the whole drilling process.

Because concrete will wear the rebar cutter quickly, it is better that you use rebar cutter only when encountering the embedded rebar.

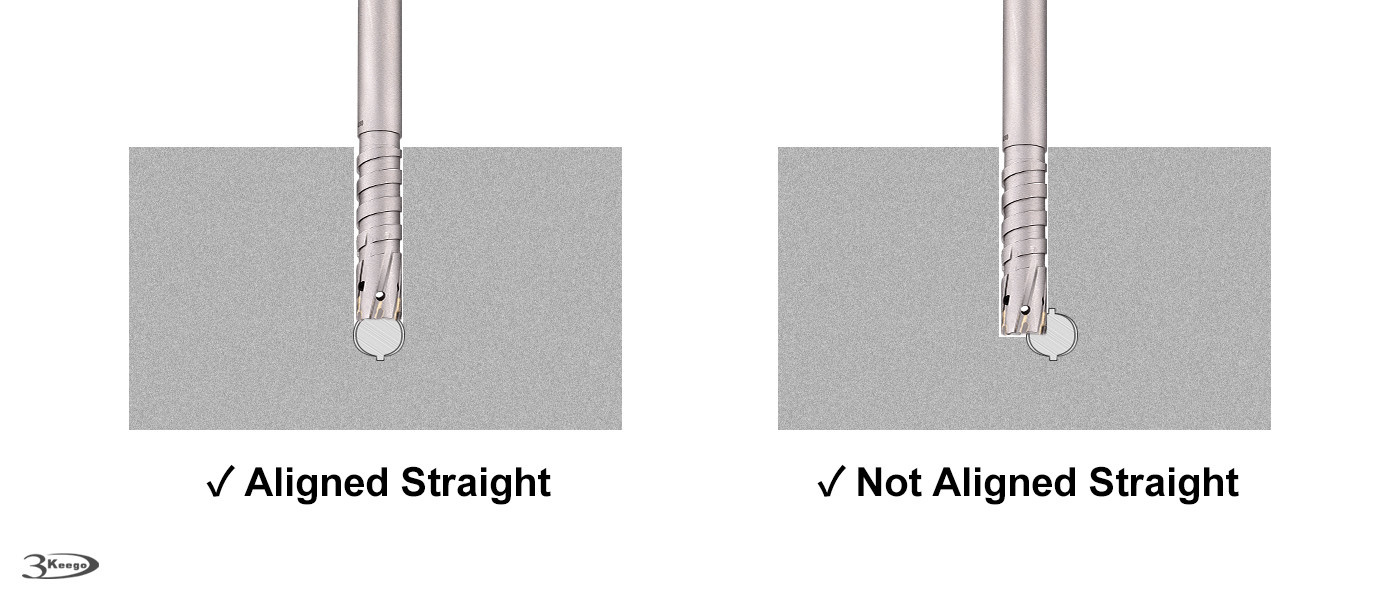

- Support and hold the rotary hammer drill properly

When drilling the concrete wall, usually vertical to the ground, it is important to hold your hammer drill with enough strength to balance the gravity. This can avoid breakage of the rebar cutter caused by pressure from portion of the weight.

- Drill at a slow RPM and proper pressure

The drilling speed for rebar should be slower than drilling the concrete. As using rotary mode to drill rebar steel, you need to put some pressure to the hammer drill until penetrating the rebar.

[ Support ]

3keego provides SDS Plus Rebar Cutter with Tungsten Carbide Tipped teeth for durability. You can search more information on our product page of HAA Rebar Cutter.

If you have any further questions, please do not hesitate to CONTACT US.

Related Articles